Yoshiyuki NOMURA, Yasushi SAITOH, Kingo FURUKAWA,

Yoshinori MINAMI, Kanji HORIUCUL and Yasuhiro HATTORI

Basic Technology R & D Department, Circuits and Connection R & D Division

AutoNetworks Technologies

Abstract-A press-fit connector for automobile airbag electronic

control units (ECUs) was developed and transferred to the mass production phase by Sumitomo Wiring Systems, Ltd. and AutoNetworks Technologies, Ltd. in 2005.

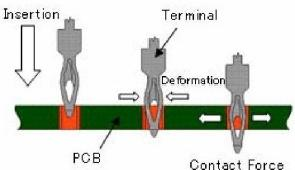

A press-fit connection is a solderless electrical connection technology, which utilizes the mechanical contact force generated between through-holes on a printed circuit board (PCB) and terminals with a width slightly larger than the through-hole diameter.

This technology has been widely noted recently as a measure against the "Lead Free Requirement" of materials comprising electric/electronic devices.

For the application of this technology to automobile connectors,we have to take into account the more severe environmentalconditions required.

Consequently, a press-fit connector for automobile airbag ECUs has been successfully developed and mass-produced from 2005.

Furthermore, the authors have also developed a new type of hard tin plating on terminals, thus preventing the scraping-off of tin during the insertion process, that could result in a short-circuit on the PCB.

Keywords- Automobile ECUs, Connection Reliability, Hard Tin

Plating, Lead-Free, Press-fit Connection.

INTRODUCTION

A. Lead Free Requirement and Press-fit Connection

There is a global tendency toward eliminating hazardous

materials from electrical/electronic devices (ex. RoHS Directive [1]). In particular, the development of lead free solder is an urgent priority for electrical/electronic industries worldwide.

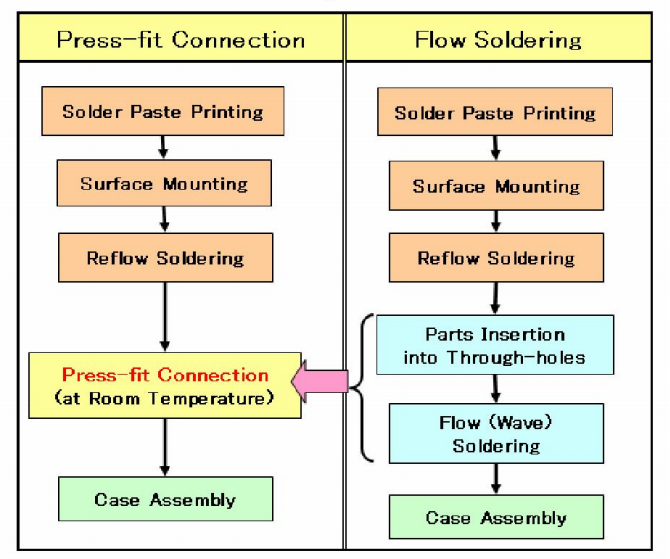

On the other hand, in the area of automotive electronic control units (ECUs), there is interest in solderless press-fit connection technology for mounting though-hole insertion type parts, like connectors, which was previously achieved by a flow or wave soldering process.

Although this technology has been conventionally adopted in the area of telecommunication equipment over the last few

decades, there have been considerable expectations of their application in automotive connectors, recently subject to measures governing lead free requirements.

A press-fit connection is a form of electrical connection technology, which utilizes the mechanical contact force generated between though-holes on a printed circuit board (PCB) and terminals with a width slightly larger than the through-hole diameter, as shown in Fig. 1.

This technology also has the additional advantages of (I)No extra heating process for surface mounted devices, (2)No need to use heat resistant plastics for the connector housing, because the terminal insertion process (i.e. Press-fit connection) is conducted at room temperature described in Table I.

Authorized licensed use limited to: Cornell University Library. Downloaded on November 11,2022 at 05:14:29 UTC from IEEE Xplore. Restrictions apply.

Post time: Dec-02-2022

Youtube

Youtube