pin inserting machine/ wire cutting stripping crimping machine/ lead cutting preforming machine

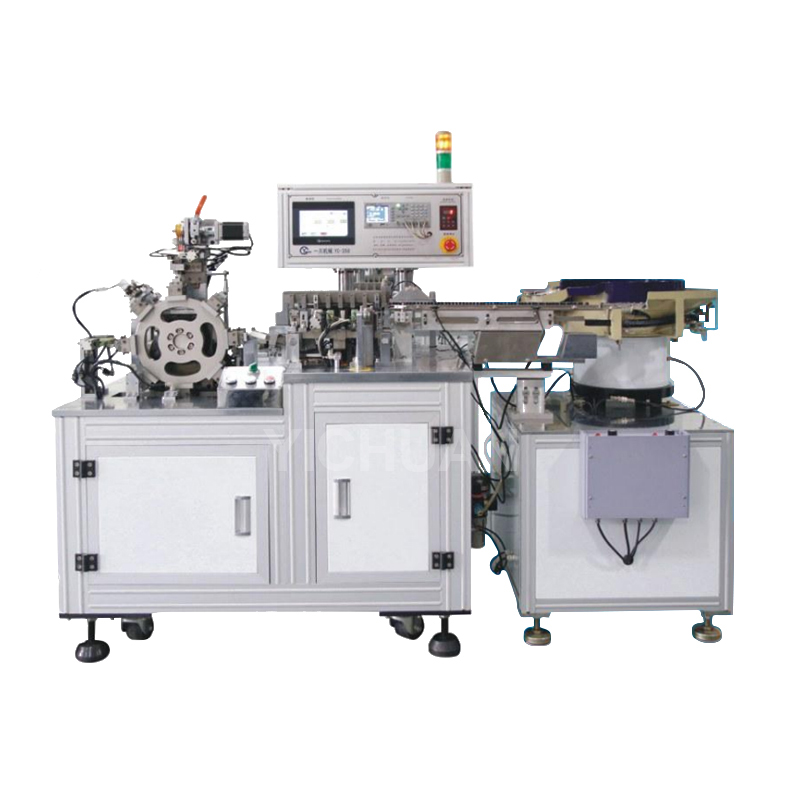

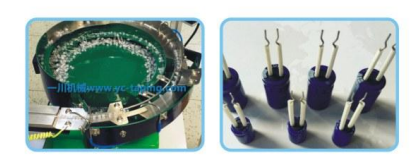

YC-350 Automatic capacitor inductor lead forming and insulation sleeve wearing machine

Equipment Characteristics

Specification

|

Power |

220V/50HZ/1KW |

|

The use of air |

4kg/cm² |

|

Production Speedmin |

100-150pcs/min |

|

Forming Lead wire distance |

7.5mm 10mm 15mm 22.5mm |

|

Cut length of the product |

2.5mm-28mm |

|

Mechanical demensions |

1500L*1000W*1500H(mm) |

|

Weight |

400KG |

About Yichuan

Dongguan Yichuan Machine Co., Ltd. was established in June, 2006 and has acted as an professional manufacturer located in the China and have many service site and distributors all over the world that produce PCBA & SMT LINE, Wire Harness Processing Machines, and semi-conductors lead forming and reel taping machines. Since then Yichuan has carried out business in this industry successfully. We are recognized by our business partners and customers alike for our ability to conduct business at the highest of standards.

Since 2016, we have developed AOI and Customized designing business as new division of the company, and worked for LED production, special wire harness processing machine, and Special PCB process etc. With experience in machine design and fabrication filed around 16 years, long term business plan is to continuously enlarge successful business in this field.

Youtube

Youtube