pin inserting machine/ wire cutting stripping crimping machine/ lead cutting preforming machine

ZX-680S Automatic LED Driver Spacer Pin Insertion Machine

Main Data Indexes

|

Overall dimension |

2250*1300*1600mm |

|

Weight |

1000KG |

|

Air |

6+/-0.5kg/cm2 ( air consumption 656 N/min ) |

|

Power |

AC220V, single-phase50/60HZ, 1.4KW |

|

Noise |

80dB |

|

Operating enviroment |

5-40℃ |

|

Humidity |

10-90%RH ( it can be used as long as there are no crystal beads in the air ) |

|

Requirements for the surronding enviroment |

no corrossive gas |

|

Movement dimension of the workbench |

X680mm, Y370mm, Multi-direction X580mm, Y370mm Bilatery |

|

Movement speed of workbench |

22.5m/min |

|

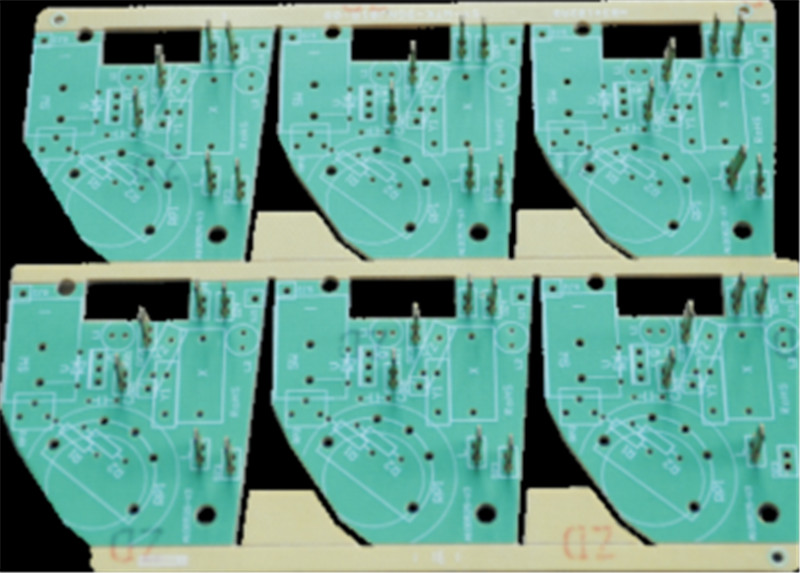

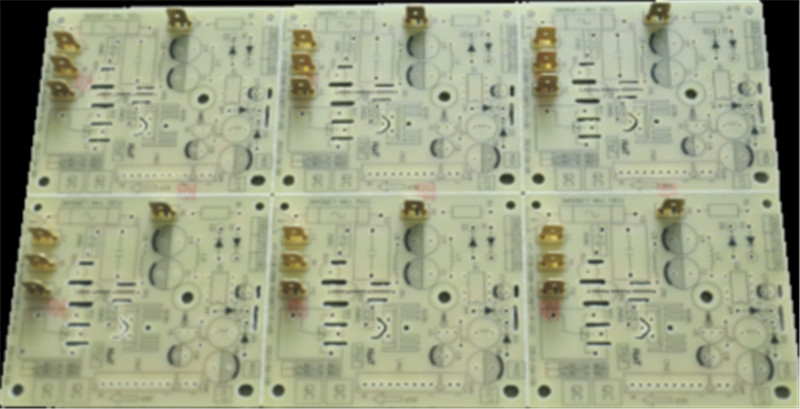

PCB electric circuit board |

500*350Max |

|

Flow direction of PCB |

L-R, R-L |

|

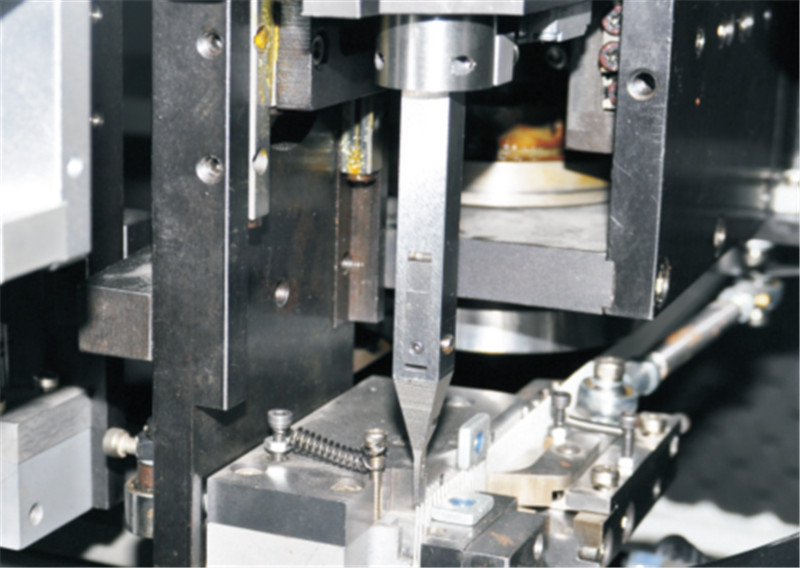

Inserting direction |

0, 90, 180, 270 degrees or multi-angle |

|

Plugging speed |

140-220PCS/min |

|

External communication funtion |

by RS-485 interface |

|

Installation time of electric circuit board |

4s |

|

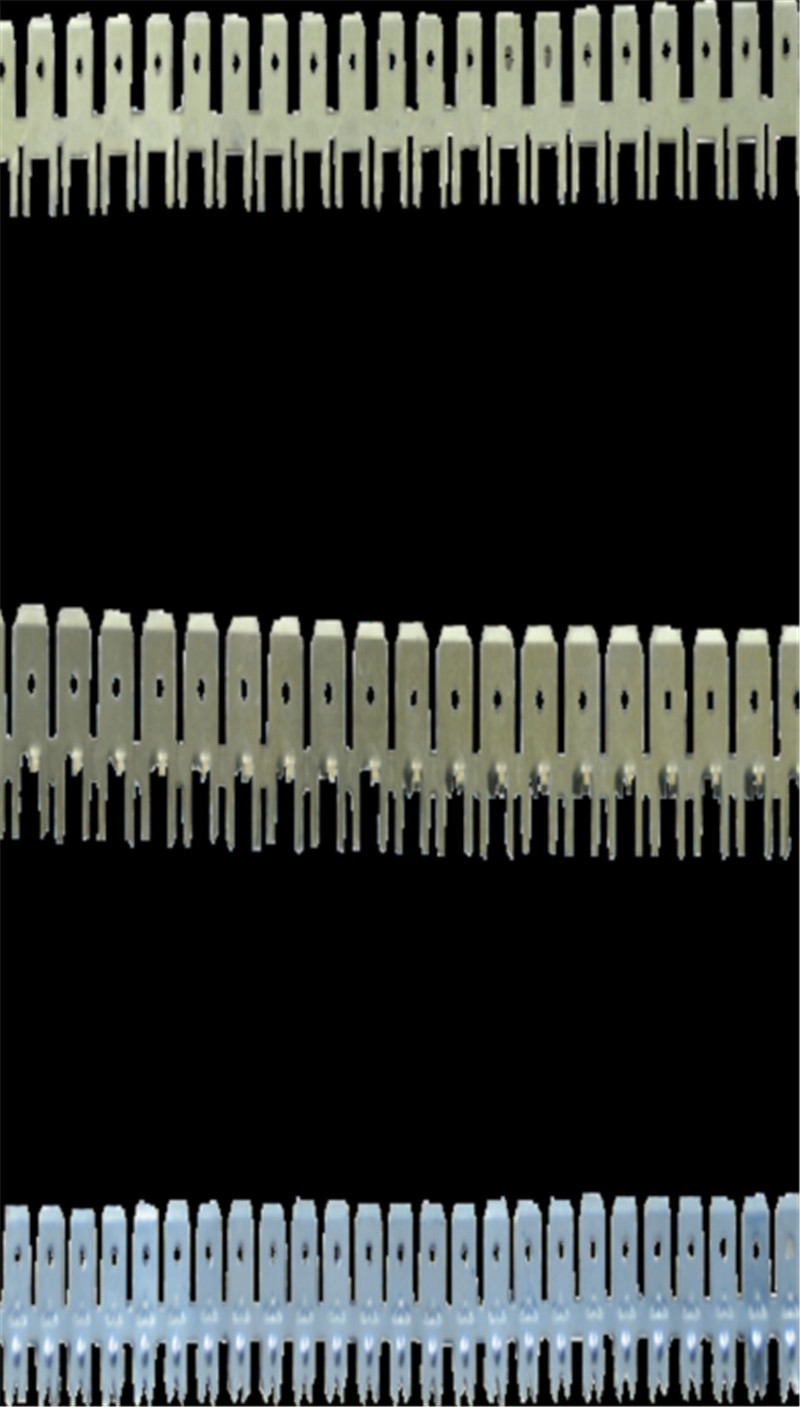

Component iserted |

all kinds of conventional and special-shape end pieces and circled pin end pieces |

|

Quantity of inserting heads |

1-3 ( based as required ) |

|

Hole correction mode |

CCD HD indusrial camera angle system |

Product Configuration

Operation system

Operating software, production data, management data, equipment parameters, editing programs, all I/O signal diagnosis, etc. running under Windows environment can be completed on the host. The interface is humanized, and the application of high-tech technology makes the equipment introduction efficient and easy to use, easy to use.

Plug in speed

0.8 seconds / piece, equipped with Panasonic AC servo drive, high speed, low noise, smooth motion.

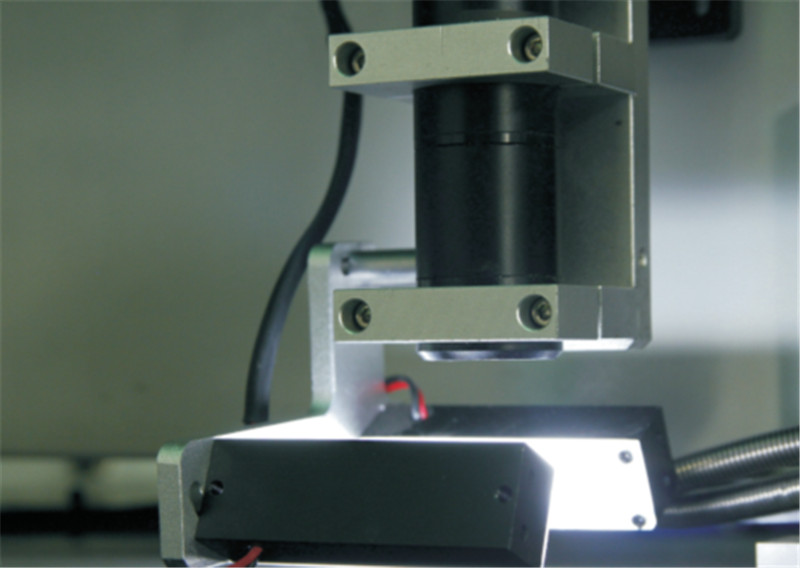

Visual System

The industrial-specific high-definition camera and the self-developed vision correction software form a vision system. The deviation between the PCB hole position and the programmed input coordinates can be quickly and automatically calibrated to match all the coordinates with the actual PCB hole position, ensuring the plug-in accuracy and greatly improving the programming efficiency.

Youtube

Youtube