A pin insertion machine, also known as an automatic press-fitting pin insertion machine, is a type of machinery used in various manufacturing processes. It is designed to insert pins into pre-drilled holes or cavities on a printed circuit board (PCB) or other electronic component. The machine provides a quick and efficient method of securely mounting pins onto PCBs, ensuring proper connection and function of electronic devices.

Pin insertion machines are used in a wide variety of industries including electronics, telecommunications, automotive and aerospace. They play a vital role in the assembly process of electronic devices, as pins are often used for electrical connections, mechanical stability, or both. These machines are able to handle different types of pins such as through-hole or crimp pins that vary in size, shape and material.

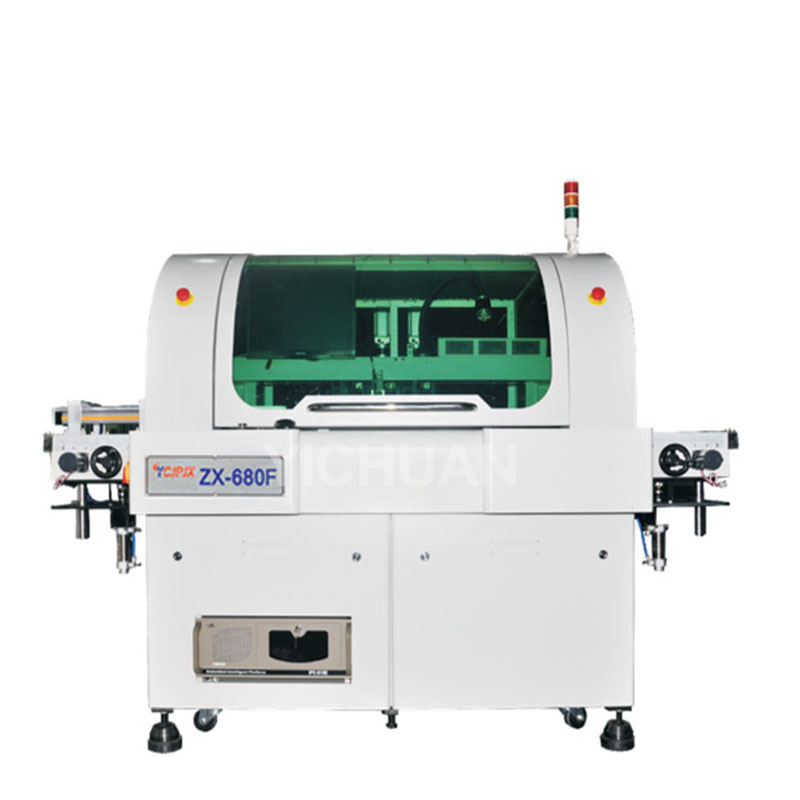

The operation of a pin insertion machine depends on precision and accuracy. It involves several steps to ensure successful pin insertion. First, the operator prepares the pin insertion machine by selecting the appropriate pin and programming the machine with the necessary parameters, such as insertion depth and speed. The machine is then loaded with the PCB or component that needs to be inserted into the pins.

Once everything is set up, the pin insertion machine performs its main function - inserting pins into designated holes on the PCB or component. This process involves the synchronized movement of several components within the machine, including the needle feeder, insertion head and PCB holding mechanism. The machine carefully aligns the pin with the hole and applies just the right amount of force to insert it securely.

Automatic pin insertion machines offer several advantages over manual methods or other types of machinery. First, they save time and labor by automating the pin insertion process, which increases productivity and reduces the chance of human error. Second, they provide precise and consistent results, ensuring pin insertion accuracy and preventing damage to PCBs or components. Finally, these machines are versatile as they can handle a wide variety of pin types and sizes, making them suitable for different applications.

In addition to these benefits, pin insertion machines are also equipped with advanced features and technologies to increase their performance and efficiency. Some machines have built-in inspection systems that detect and reject defective pins or misaligned holes. Others include automatic pin alignment mechanisms or vision systems to improve accuracy. These additional features help to improve the overall reliability and effectiveness of the pin insertion process.

The pin insertion machine is an important tool in the manufacturing process of electronic equipment. It enables efficient and precise insertion of pins into a PCB or other component, ensuring proper electrical connection and mechanical stability. These machines offer several advantages such as increased productivity, accuracy and versatility. With its advanced features and technology, pin insertion machines continue to evolve to meet the increasing demands and complexities of modern electronics assembly.

Post time: Aug-22-2023

Youtube

Youtube