pin inserting machine/ wire cutting stripping crimping machine/ lead cutting preforming machine

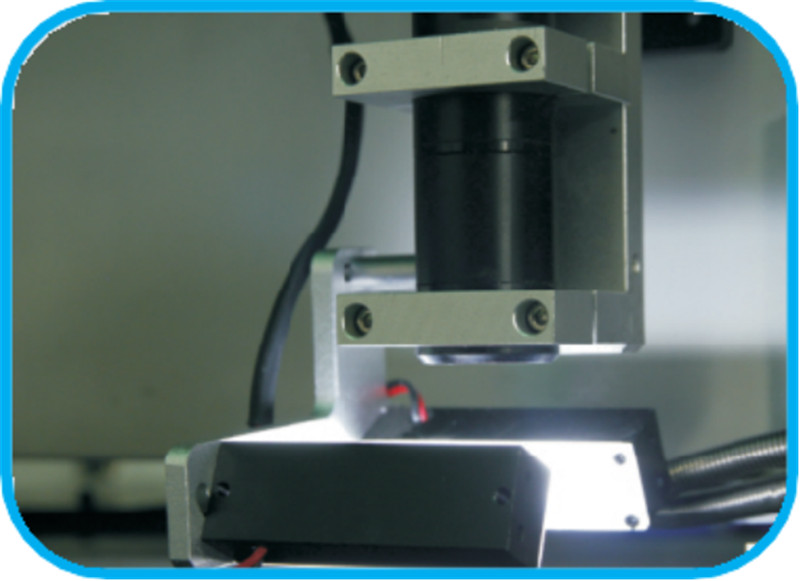

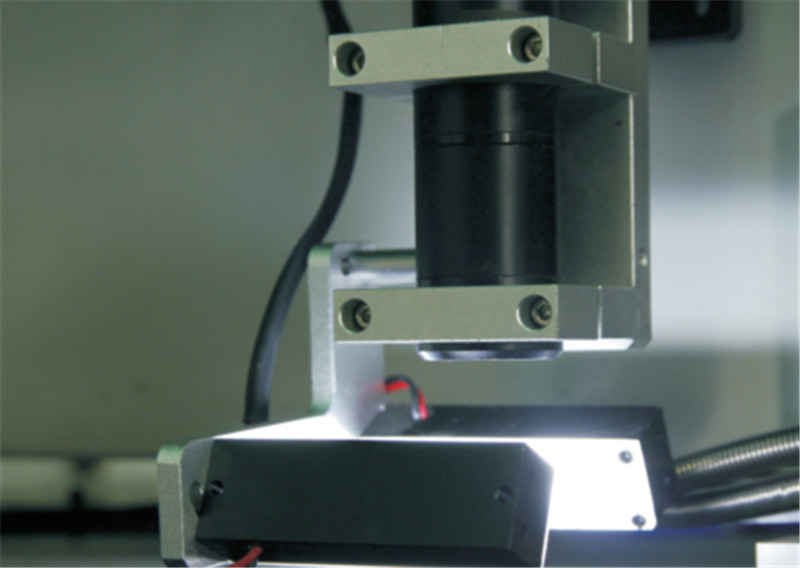

ZX-650S Automatic Press-fit Pin Insertion Machine

ZX 650S pin insertion machine Video

Automatic Pin Insertion / Pressfit Machine Operation Video

Our Advantage

1.Easy operating modes

2.Easy setting, edge guiding

3.Cutters re-grinded

4. Avoid micro-cracks

5. Structural precision, the load evenly, to eliminate internal stress

6. Safe, easy to operate

1. Promise day technical support services.

2. Limit the handling of complaints, half an hour back to customers.

3. Depanel Experts, the provision of professional PCB sub-programme.

4. Reliable machine maker, we get Experts--15, each one got over 6 years experience, equipment quality will be satisfying.

This concept also allows to easily integrate future projects in this production line or adapt and reuse the same machine on different lines.

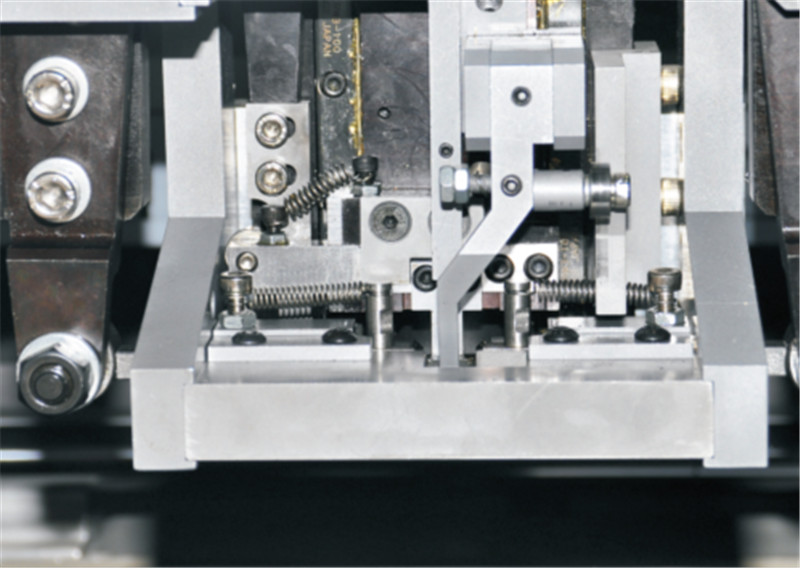

The new clamp and its optimized system now allow to insert terminals in the desired orientation rotating the insertion handle.The option of inserting two terminals in one clamp eliminates the down time within the movement between clamps, reducing fixed times up to 30% .

Specification

|

Overall dimension |

2250*1300*1600mm |

|

Weight |

1000KG |

|

Air |

6+/-0.5kg/cm2(air consumption 656N/min) |

|

Power |

AC220V, single-phase50/60HZ, 1.4KW |

|

Noise |

80dB |

|

Operating enviroment |

5-40℃ |

|

Humidity |

10-90%RH(it can be used as long as there are no crystal beads in the air) |

|

Requirements for the surronding enviroment |

no corrossive gas |

|

Movement dimension of the workbench |

X680mm, Y370mm, Multi-direction X580mm, Y370mm Bilatery |

|

Movement speed of workbench |

22.5m/min |

|

Rotary table of the workbench |

|

|

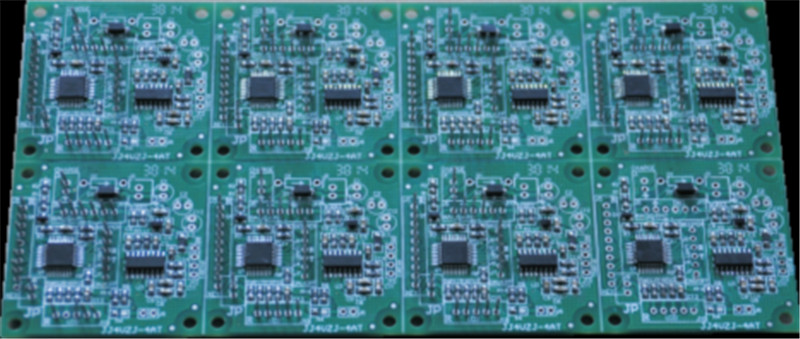

PCB electric circuit board |

500*350Max |

|

Plugging speed |

400PCS/min |

|

Installation time of electric circuit board |

4s |

|

Component iserted |

8-12mm long square and round steel pins |

|

Q'ty of insertinf Heads |

1 |

|

Hole correction mode |

by the angle system of the machine |

|

Computor control system |

Intel Corei3 CPU Windows operation system |

|

Display system |

15inch color LCD |

|

Feeding system |

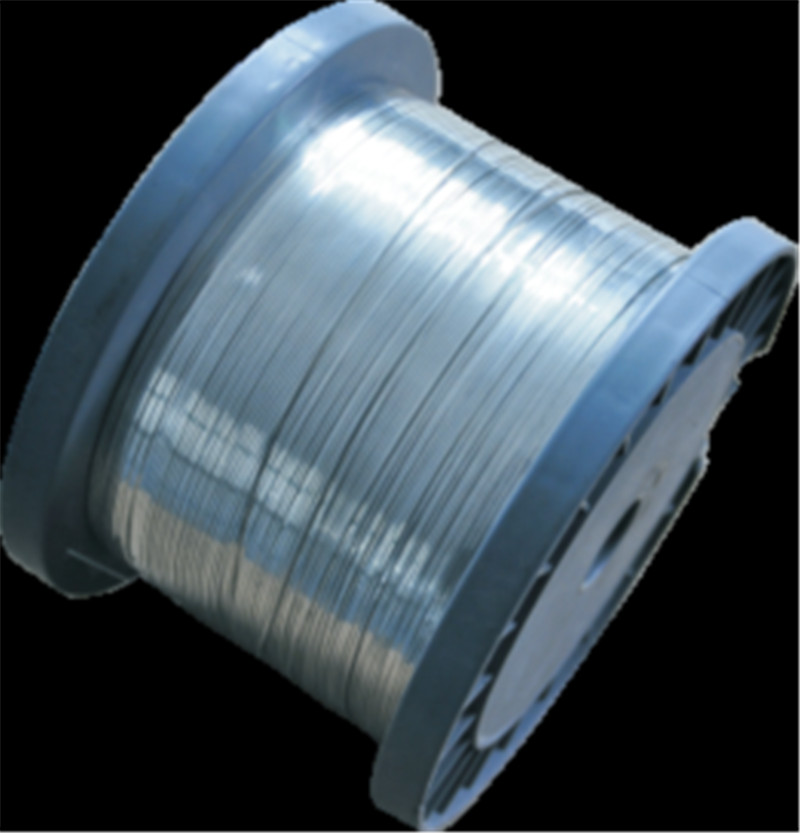

rolling feeding system |

Product Details

Youtube

Youtube