pin inserting machine/ wire cutting stripping crimping machine/ lead cutting preforming machine

Resistor Forming Lead Preforming Machine YC-290A

Video

Equipment Characteristics

The machine performs several important functions to prepare the leads of resistors for efficient and accurate installation:

Lead Bending: The machine is equipped with bending mechanisms that can bend the leads of resistors to the required angles or shapes. This ensures the leads are properly positioned and aligned for insertion into PCBs.

Lead Straightening: Often, resistor lead forming machines also straighten the leads, ensuring they are free from any kinks or distortions that could affect their placement on the PCB.

Lead Cutting: Some machines also incorporate cutting mechanisms to trim the leads to the desired length after they have been bent and straightened. This helps ensure consistent lead lengths across resistors.

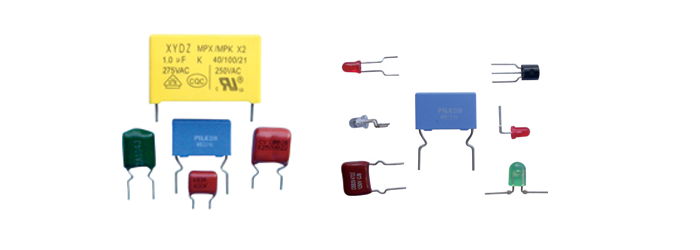

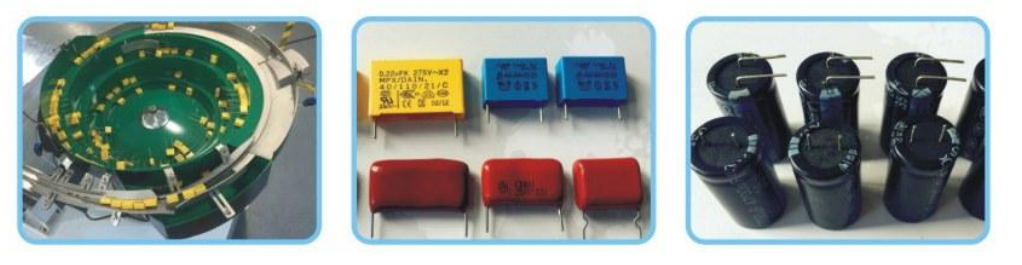

Applicable elements

LED/light-emitting diodes, transistors, aluminum, electrolytic capacitors,mentally film capacitors, inductors diodes, resistors and others.

Specification

|

Power |

220V/50HZ/1.5KW |

|

The use of air |

4kg/cm² |

|

Production Speedmin |

160-230pcs/min |

|

Forming Lead wire distance |

2.0mm 2.5mm 5.0mm 7.5mm 10mm |

|

Cut length of the product |

2.5mm-28mm |

|

Mechanical demensions |

2300L*1200W*1500H(mm) |

|

Weight |

400KG |

|

Packing type |

Bulk |

Factory

Automotive Electrical Department

Mainly Manufacturing Insertion machine for automotive fuse box, Homeappliance power chip insertion. and high speed pin insertion machine.

Harness Processing Department

Mainly Manufacturing Harness Processing machines like:Wire stripping, tinning machine, tinning and crimping machine,crimping and housing insertion machine.

Semiconductor Department

Mainly Manufacturing Reel taping machine, semiconductor forming machine.

Youtube

Youtube