pin inserting machine/ wire cutting stripping crimping machine/ lead cutting preforming machine

Component Lead Forming Machine Resistor Lead Cutting Machine

Resistor Lead Cutting Machine Video

Specification

|

Power |

220V/50HZ/1.5KW |

|

The use of air |

4kg/cm² |

|

Production Speedmin |

180-230pcs/min |

|

Forming Lead wire distance |

2.0mm 2.5mm 3.5mm 5.0mm 7.5mm 10mm 15mm |

|

Distance From Indexholr Tocapacity Base |

16.5mm-24.5mm |

|

Diatance/Diameter |

12.7mm/4.1mm or 15.0mm/4.1mm |

|

Mechanical demensions |

2300L*1200W*1500H(mm) |

|

Weight |

700KG |

|

Packing type |

Box or package |

|

Length of the product |

5-35mm |

|

Specifications of Processed |

The diameter of 3-10 or the wide of≤customized) |

Applicable elements

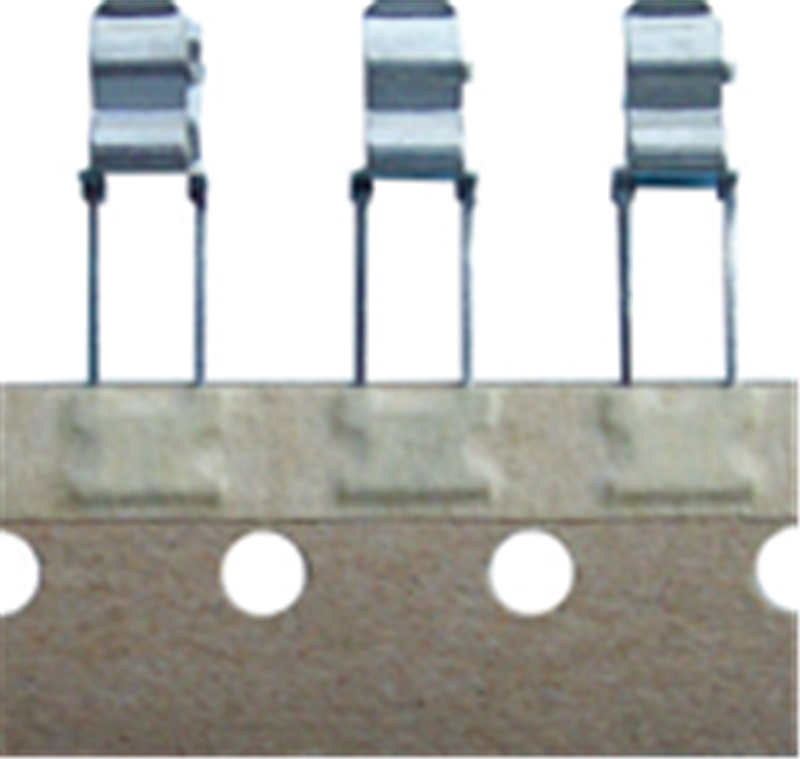

The machine typically consists of a bed or platform on which the components are placed, and a set of movable blades or dies used to shape and cut the leads. The operator can adjust the position and depth of the blade to obtain the desired wire shape and length.

Component lead forming machines are used to automate the process of forming and cutting the leads of resistors, which are typically straight components with long leads at both ends. Using this machine, leads can be bent, shaped or cut to the desired size or configuration for easy insertion into a PCB (Printed Circuit Board) during assembly.

Equipment Characteristics

Youtube

Youtube