pin inserting machine/ wire cutting stripping crimping machine/ lead cutting preforming machine

Utilize advanced forming and reel taping machines YC-320

Automatic LED Lead Cutting Video

Product Description

Automatic LED capacitor are equipped with cutting-edge technology and innovative features. Their versatility allows you to handle a variety of products and materials. Whether you need to tape electrical components or secure automotive parts, these machines can handle it.

One of the main advantages of a reel taping machine is its ability to apply lead cutting accurately and evenly. This eliminates errors and ensures consistent quality throughout the production line. These machines use advanced sensors and controls to ensure precise tape alignment and tension.

Specification

|

Power |

220V/50HZ/1.5KW |

|

The use of air |

4kg/cm² |

|

Production Speedmin |

180-230pcs/min |

|

Forming Lead wire distance |

2.0mm 2.5mm 3.5mm 5.0mm 7.5mm 10mm 15mm |

|

Distance From Indexholr Tocapacity Base |

16.5mm-24.5mm |

|

Diatance/Diameter |

12.7mm/4.1mm or 15.0mm/4.1mm |

|

Mechanical demensions |

2300L*1200W*1500H(mm) |

|

Weight |

700KG |

|

Packing type |

Box or package |

|

Length of the product |

5-35mm |

|

Specifications of Processed |

The diameter of 3-10 or the wide of≤customized) |

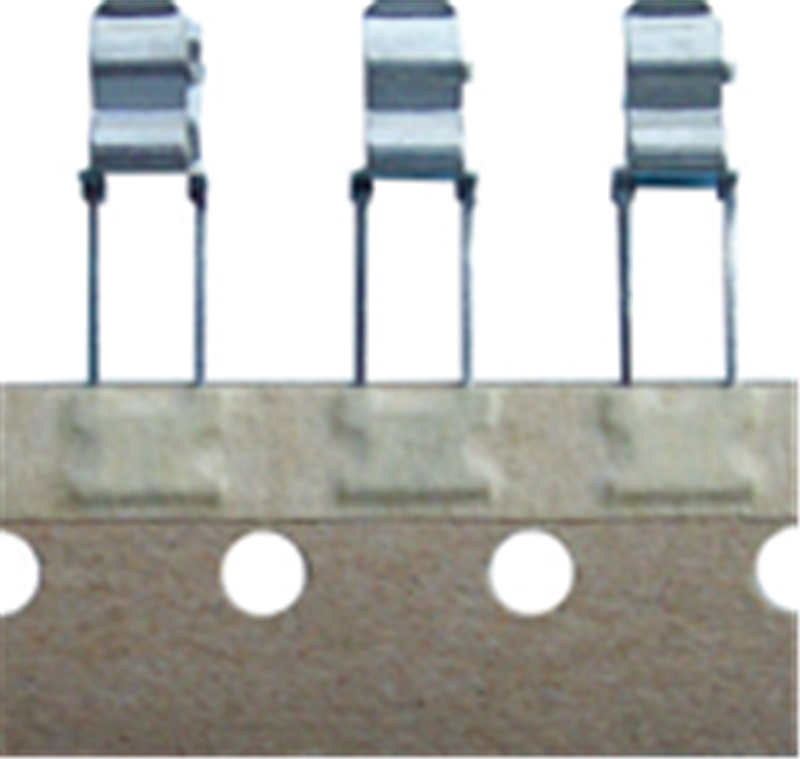

Applicable elements

LED/light-emitting diodes, transistors, aluminum electrolytic capacitors, metallic film capacitors, inductors, crystal oscillators, fuses, tact switches and other touch-line components.

Equipment Characteristics

Youtube

Youtube